Prototyping

From design to product: thirty years of experience and innovative technologies

In order to meet the requirements of precision, we perform rigorous dimensional scrutiny of the parts being processed during the entire production cycle. For this purpose we use a dedicated control air-conditioned room, equipped with certified measuring instruments, including a numerical control three-dimensional measurement machine.

The production phase concludes with dimensional testing of the manufactured parts. On request, the Company provides certification of the measurements taken.

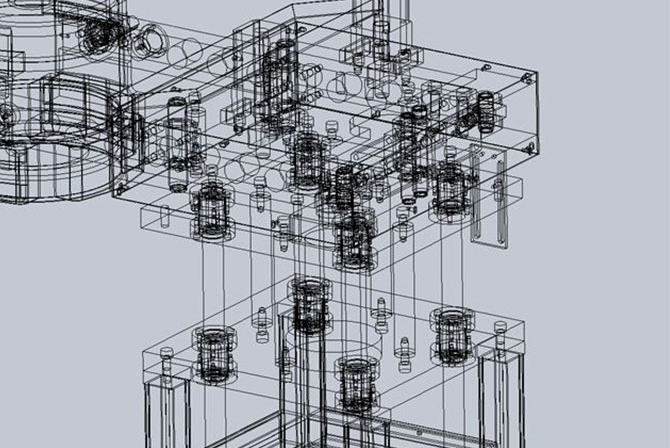

This operation is essential when providing special or complex equipment employing several elements mounted in a single structure.

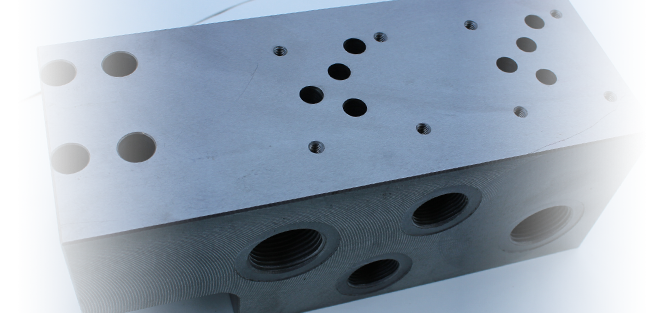

The machinery allows a plurality of processes, including piece cutting, turning and automatic milling, grinding, and wire, TIG and laser welding, gearing, deep drilling, grooving, etc.